TUBE BENDING & METAL FABRICATION CAPABILITIES

QUALITY TUBULAR PRODUCTS AND WELDED ASSEMBLIES

Home /

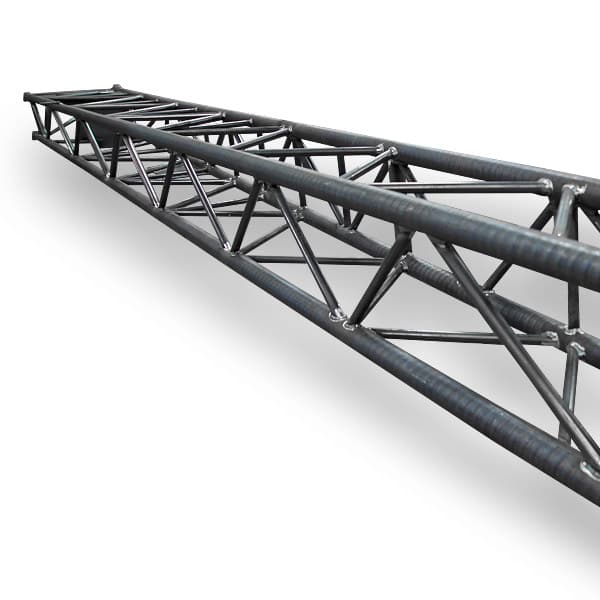

Heavy Duty

Heavy-duty metal fabrications from Leonhardt include tubular products and welded assemblies manufactured to meet the demands of OEM products, industrial applications, and custom metal fabrication requirements.

Tube Bending

Leonhardt's ISO certified team and specialized CNC tube bending equipment can handle production runs and complex multi-radius projects with ease.

Tube Fabrication

Companies including OEMs in the automotive industry depend on Leonhardt to fabricate, assemble, and manage the supply chain for tubing and tubular products critical to their manufacturing processes.

End Forming

Leonhardt offers tube end forming capabilities to meet most applications and design requirements including tube swaging, flaring, flanging, beading, bulging, chamfering, crimping, tapering, notching, rounding, and more.

Decorative

Leonhardt Manufacturing specializes in producing fabricated tubular metal parts for applications requiring highly decorative, shiny, finely polished, and superbly finished end products.

Polishing & Chrome Plating

Companies rely on Leonhardt's excellence in manufacturing, rigorous quality control, and superior metal finishing processes combine to deliver superior chrome plating and metal polishing services.

Contract Manufacturing

Leonhardt Manufacturing is a world-class contract manufacturing partner specializing in highly decorative tube bending and tubing fabrications.

Additional Fabrication Services

From our 95,000 square foot facility, Leonhardt Manufacturing provides a comprehensive assortment or metal fabrication services including Stamping, Welding, Brazing, Metal Finishing, Sub-Assembly Construction, Prototyping & Design, and Supply Chain Management.

RANGE OF CAPABILITIES

Leonhardt Manufacturing produces quality tubular products and welded assemblies that combine CNC bent tubes, stampings, machined parts and a variety of finishes from paint and powder to decorative chrome. Leonhardt’s 95,000 square foot facility features skilled workers and specialized equipment designed to fabricate, manufacture and finish metal products and components with the highest degree of quality, accuracy and efficiency.

View our video library.

Core Capabilities

- CNC Tube Bending

- Tube Fabrication

- MIG and TIG Welding

- Robotic MIG Welding

- Aluminum Welding

- Design for Manufacturability

- Brazing

- Metal Stampings

- Polishing & Chrome Plating

- Sub-Assemblies

Value Added Core Competencies

- Prototype & Development

- Design for Manufacturability

- Outsourced Manufacturing

- Supply Chain Management

- Lean Manufacturing

- Cost Containment

Materials & Metals

- Aluminum

- Steel

- Stainless Steel

- Galvanized Steel

- Cold Rolled Electric Weld

- DOM Tubing

Shapes

- Round

- Square

- Oval

- Rectangular

Sample of Manufactured Products

- Decorative, Shiny, Tubular Assemblies

- Chairs

- ATV/Motorcycle Chassis

- ATV/ Motorcycle Handle Bars

- Motorcycle Engine Guards

- Motorcycle Saddlebag Rails

- Grab Handles

- Oil Lines, Tubes and Assembles

- Composter Frames

- Heavy Duty Welded Assemblies

- Crane Jibs

- Structural Tubing and Welded Assemblies

APPROACH TO MANUFACTURING

Leonhardt’s approach to manufacturing and customer satisfaction focuses on delivering exceptional products and services through proven processes and tested capabilities.

Lean manufacturing models are developed and followed for every product that is manufactured and each component that is fabricated. In addition, Leonhardt’s wide range of tube bending, welding and metal fabrication capabilities are continually improved upon and performed to ISO Certification and AWS standards. Enforcement of quality standards throughout the manufacturing process are critical to remaining a world-class manufacturer.

What makes Leonhardt different?

A customer-centric philosophy and dedication to understanding and meeting client needs is central to Leonhardt’s approach to manufacturing. Leonhardt’s approach offers their customers:

Leonhardt provides companies with a flexible approach to manufacturing processes. From scaling up through adding floor space and equipment to mid-stream product design alterations, Leonhardt’s flexibility ensures that project goals are successfully achieved – on time, on budget and without sacrificing quality.

Control of supply chain and inventory, consolidation of vendors and reduction in expenses are all reasons OEMs choose Leonhardt as a manufacturing partner. Leonhardt allows clients more control to manage cash flow, mitigate risk and maximize assets.

A customer-centric manufacturer, Leonhardt’s responsiveness to client needs, changes in inventory and/or product demand and alterations to product designs is unparalleled in the industry.

Finally, by combining all of these unique differentiators, companies can take advantage of the customization Leonhardt provides. From contract manufacturing that incorporates design assistance, supply chain management and value added services, to prototyping and product ramp up, Leonhardt affords clients a custom approach to manufacturing that is proven to deliver results.

APPLICATIONS

Markets

- ATV/RV

- Boating

- Motorcycle

- Furniture

- Fitness Equipment

- Industrial Equipment

- Transportation equipment

- Mass Transit

- Emergency Vehicles

- Medical Device and Equipment

Common Products Manufactured

- Complicated, Decorative, Shiny, Tubular Assemblies

- Chairs

- ATV/Motorcycle Chassis

- ATV/ Motorcycle Handle Bars

- Motorcycle Engine Guards

- Motorcycle Saddlebag Rails

- Grab Handles

- Oil Lines, Tubes and Assembles

- Composter Frames

- Heavy Duty Welded Assemblies

- Crane Jibs

- Structural Tubing and Welded Assemblies

JOB STORIES

Leading U.S. Manufacturer Partners with Leonhardt for Contract Manufacturing Solution

Partnering with Leonhardt Manufacturing to find a contract manufacturing solution allowed one U.S. water service manufacturer reduced their supply base and produce a product that was competitive in quality and cost.

Outsourced Manufacturing for the Mass Transit Industry

After evaluating multiple contract outsourcing vendors, a leading manufacturer of passenger rail car seating chose Leonhardt Manufacturing as their preferred partner because they offered a complete suite of engineering, fabrication, welding, and polishing services delivering a turnkey solution.

Industrial Crane Manufacturer Relies on Leonhardt for Welding and Manufacturing

When a best-in-class manufacturer of industrial cranes needed a manufacturing partner to fabricate large crane jib assemblies, Leonhardt's demonstrated commitment to quality, customer service, and range of heavy-duty metal fabrication capabilities necessary to take on the project helped them deliver the results the company needed with a JIT supply method.

Testimonial from a Supplier of Consumer Gardening Products

Leonhardt Manufacturing's end-to-end services help consumer product brands at every stage of their manufacturing process. We proudly form long-lasting relationships delivering quality and value for our customers.

AME Features Tour of Leonhardt Manufacturing’s LEAN Facility

Leonhardt Manufacturing was proud to be a featured stop for the Association for Manufacturing Excellence tour showcasing their excellence in LEAN manufacturing techniques including Value Stream Mapping, cellular manufacturing, Kanban, Poka-Yoke, and visual management.

Why Outsource your Manufacturing to Leonhardt?

Reshoring the manufacturing of parts or components to Leonhardt Manufacturing allows reduces your production costs and allows you to focus on your core business.