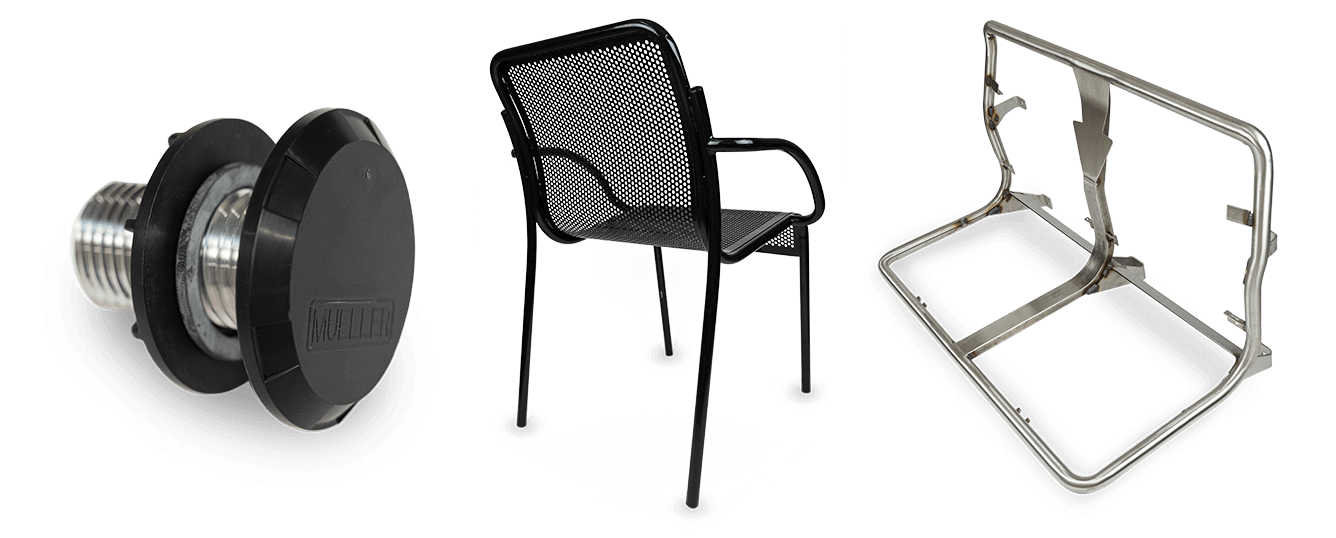

DECORATIVE FABRICATED METAL PRODUCTS

Tubular products with world-class finishes manufactured through extensive tube fabrication capabilities, rigorous quality control and metal finishing processes second to none.

CONTRACT MANUFACTURING

From prototyping and lean manufacturing to cost containment and supply chain management, find out why OEMs depend on Leonhardt as a manufacturing partner.

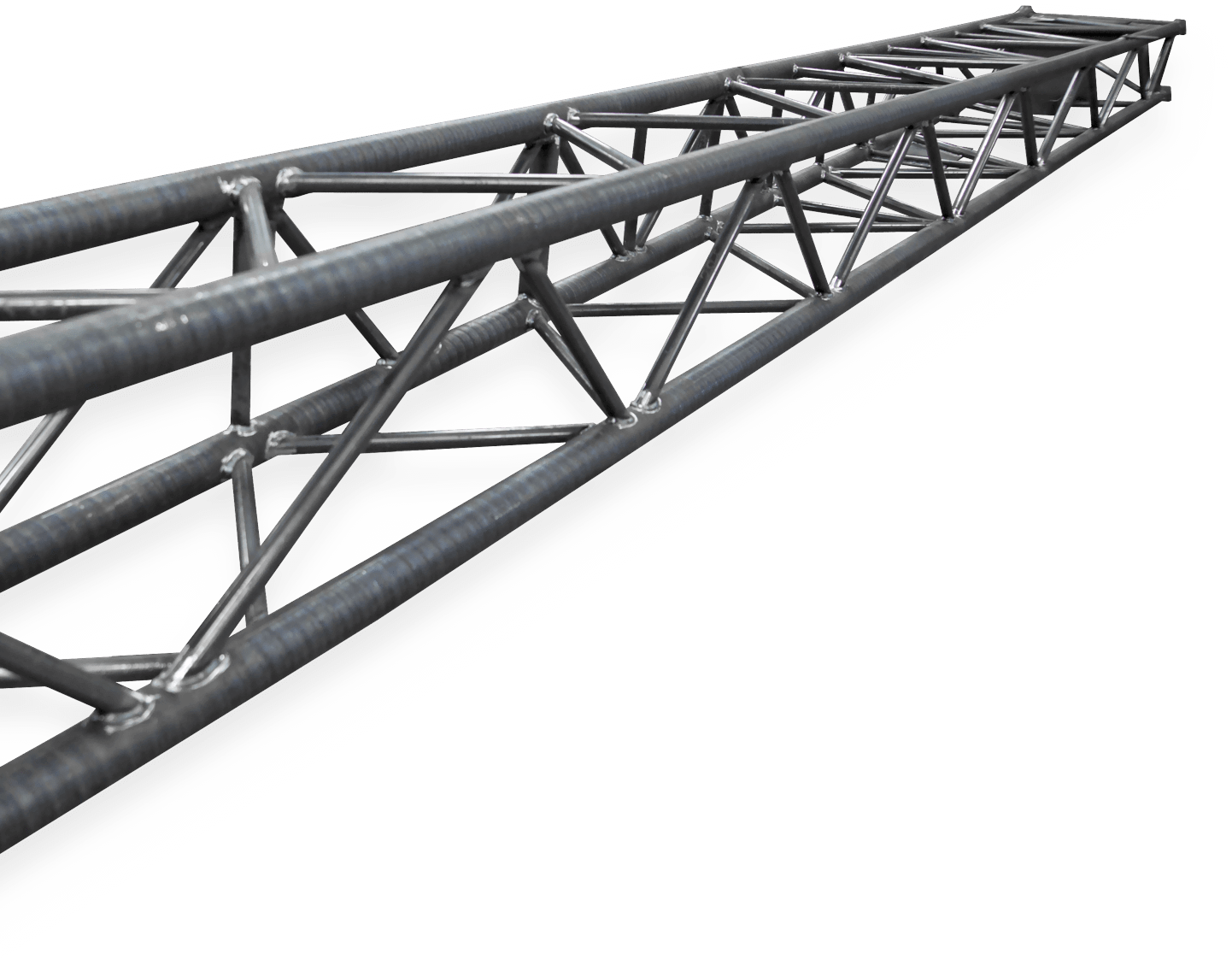

HEAVY DUTY PRODUCTS

Tube bending, welded assemblies and tube fabrication capabilities proven to deliver results for a wide range of industrial and heavy duty applications.

CAPABILITIES

Leonhardt offers a full range of tubing fabrication capabilities, as well as services including sub-assemblies, welding and brazing, metal finishing, metal stampings, prototyping, and supply chain management.

NEWS AND UPDATES

Choosing the Right Contract Manufacturer: A Guide for Success

In today's dynamic business world, outsourcing manufacturing processes has become essential for companies aiming to optimize efficiency, cut costs, and concentrate on core competencies. Explore essential factors in selecting the ideal contract to find your perfect partner to maximize business potential.

Contract Manufacturing for Tube Bending

Unlock the potential of contract manufacturing for tube bending with our beginner's guide. Learn how this model can save costs, provide expert assistance, and offer unmatched flexibility for your projects. Discover the steps to get started and overcome common challenges, ensuring your venture into contract manufacturing leads to success.

Material Selection: Beyond the Bend in Tube Fabrication

Material selection in metal tube bending is a crucial factor that affects everything from mechanical properties to corrosion resistance, making it essential for industries spanning from furniture design to vehicles.

WE TAKE QUALITY SERIOUSLY

Excellence in Manufacturing

From critical supply chain management for OEMs to lean manufacturing solutions designed to reduce costs, Leonhardt helps companies: Grow Revenues, Reduce Expenses, Improve, Cash Flow, Manage and Mitigate Risk, Maximize Asset Utilization.