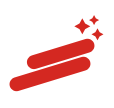

DECORATIVE FABRICATED METAL PRODUCTS

Tubular products with world-class finishes manufactured through extensive tube fabrication capabilities, rigorous quality control and metal finishing processes second to none.

CONTRACT MANUFACTURING

From prototyping and lean manufacturing to cost containment and supply chain management, find out why OEMs depend on Leonhardt as a manufacturing partner.

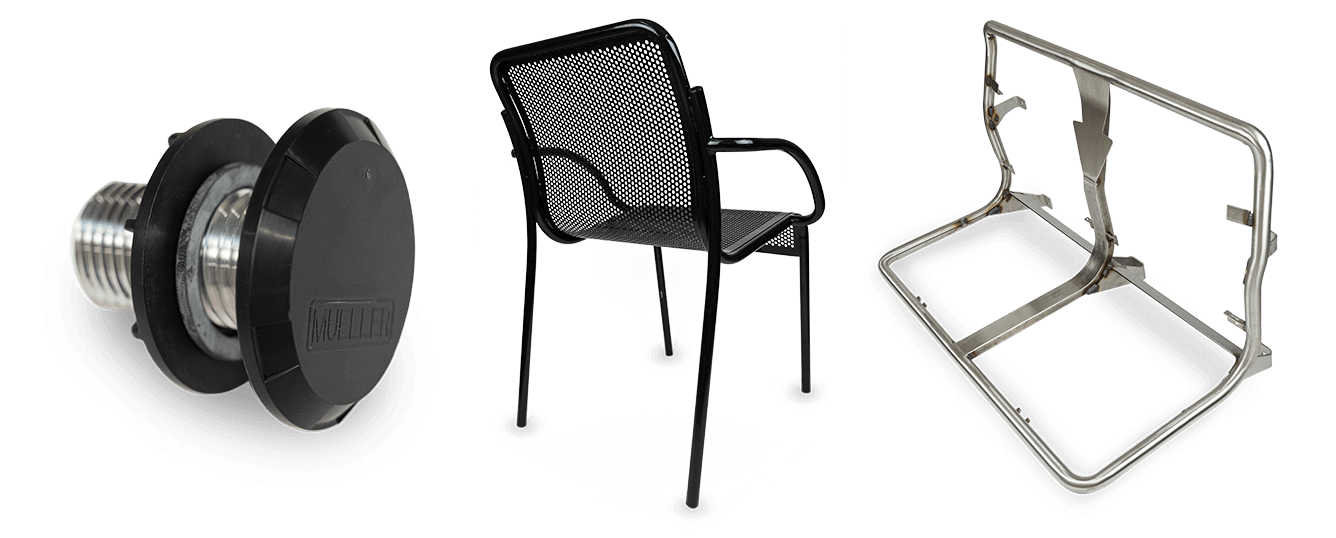

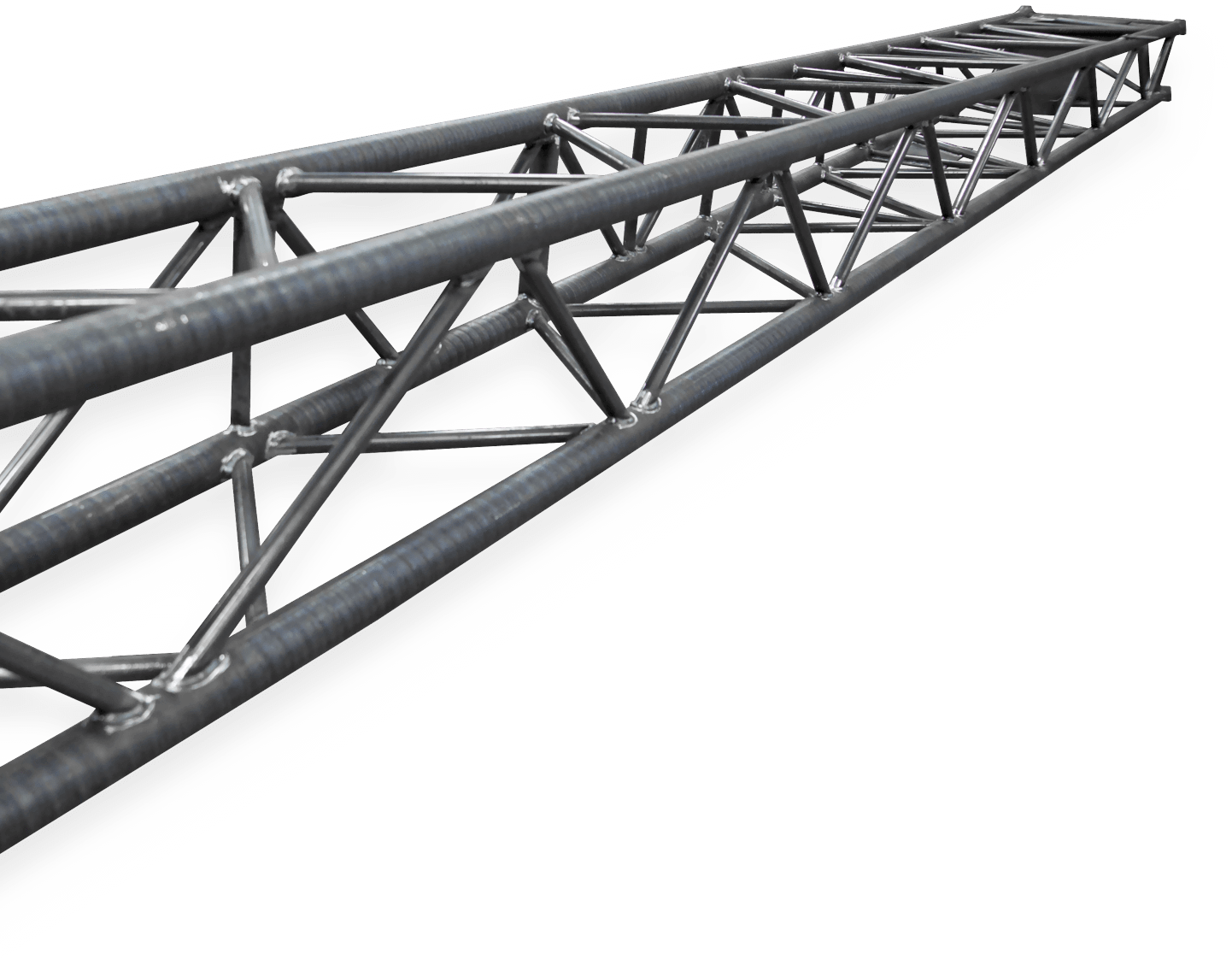

HEAVY DUTY PRODUCTS

Tube bending, welded assemblies and tube fabrication capabilities proven to deliver results for a wide range of industrial and heavy duty applications.

CAPABILITIES

Leonhardt offers a full range of tube and sheet metal fabrication capabilities, as well as services including sub-assemblies, welding and brazing, metal finishing, metal stampings, prototyping, and supply chain management.

NEWS AND UPDATES

The Manufacturer’s Guide to On-Time Delivery (OTD)

Improve on-time delivery by defining OTD clearly, measuring supplier performance, diagnosing late shipments, and building a more stable, reliable supply chain.

How to Calculate the Weight of Steel Tubing

Learn how to calculate steel tube weight quickly and accurately with formulas for round, square, and rectangular tubing — plus Excel-ready equations and pro tips from Leonhardt Manufacturing.

Precision Metal Fabrication: The Hidden Foundation of AI

Artificial intelligence depends on more than data and algorithms. Its success is grounded in the physical world, where precision metal fabrication provides the reliable, repeatable components AI infrastructure requires.

WE TAKE QUALITY SERIOUSLY

Excellence in Manufacturing

From critical supply chain management for OEMs to lean manufacturing solutions designed to reduce costs, Leonhardt helps companies: Grow Revenue, Reduce Expenses, Improve Cash Flow, Manage and Mitigate Risk, Maximize Asset Utilization.