ISO 9001: Elevating Quality Assurance in Contract Manufacturing

In the dynamic world of contract manufacturing, where precision, reliability, and customer are paramount, quality control stands as the cornerstone of success. Whether it’s fabricating intricate metal components or bending tubes to exact specifications, maintaining rigorous standards is non-negotiable. Let’s explore the indispensable role of quality control in contract manufacturing and how ISO 9001 certification serves as a guiding force in this endeavor.

Understanding Quality Control in Contract Manufacturing

Quality control encompasses a set of processes and procedures designed to ensure that products meet specified standards and customer requirements. It involves meticulous attention to detail at every stage of the manufacturing process, from sourcing raw materials to delivering the final product.

Why is Quality Control Important in Contract Manufacturing?

In contract manufacturing, companies produce goods on behalf of others. This places a significant responsibility on manufacturers to uphold the quality standards set by their customers. Effective quality control is essential for several reasons:

- Maintaining Trust: Clients entrust manufacturers with their product designs and specifications. Consistently delivering high-quality products builds trust and fosters long-term partnerships.

- Safeguarding Reputation: A reputation for quality can set a manufacturer apart from competitors and attract new business opportunities. Conversely, poor quality can damage reputation and result in lost contracts.

- Ensuring Compliance: Contract manufacturers must adhere to industry standards, regulatory requirements, and customer specifications. Quality control processes help ensure compliance and prevent costly mistakes.

Key Components of Quality Control in Contract Manufacturing

- Material Inspection: The process begins with thorough inspection of raw materials to ensure they meet quality standards and specifications. Production begins after identifying and addressing any defects or discrepancies.

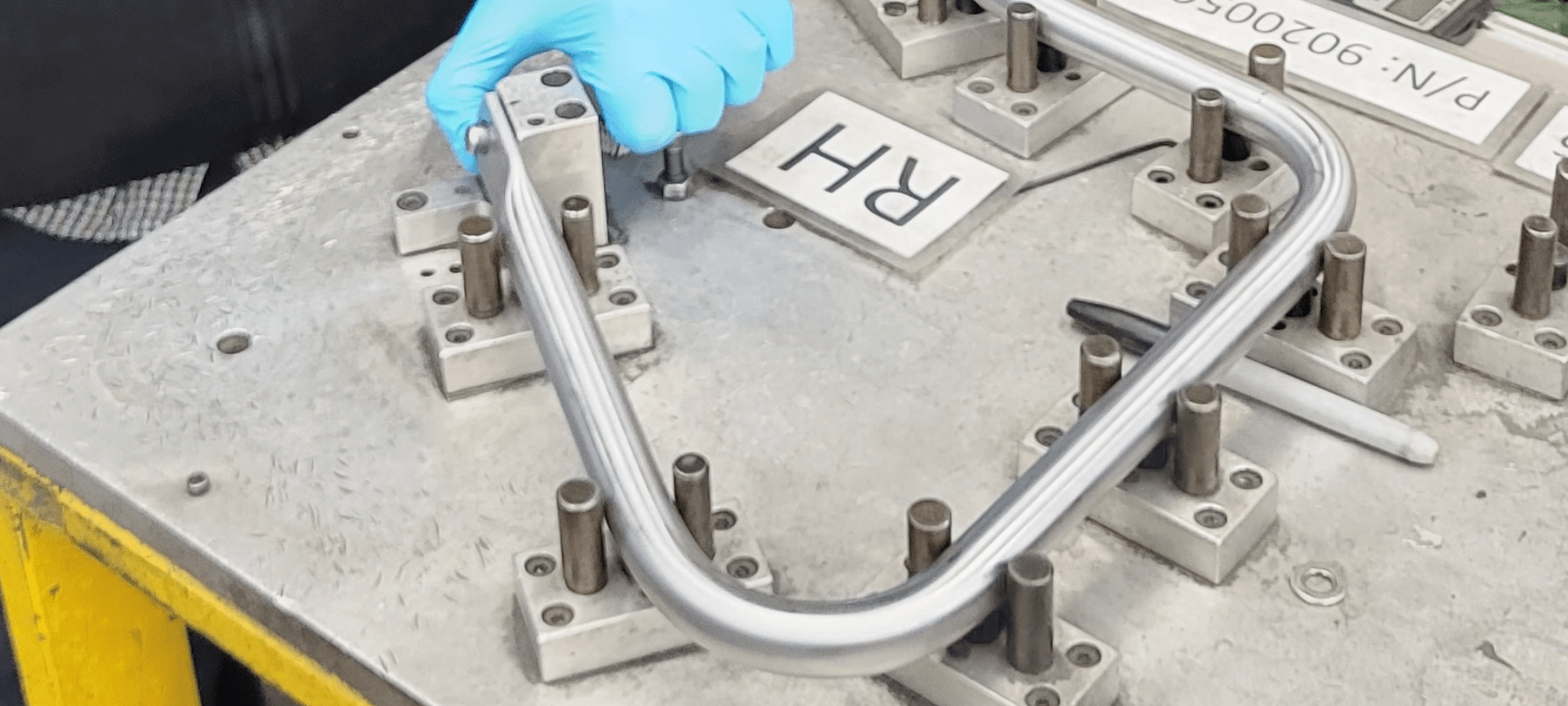

- In-Process Checks: Throughout the manufacturing process, technicians conduct regular checks to verify dimensions, tolerances, and structural integrity. Early detection of deviations allows for timely adjustments and prevents defects from propagating.

- Final Product Testing: The final step involves rigorous testing of completed components to confirm adherence to specifications and performance criteria. This may include dimensional inspections, pressure testing, and functional testing to ensure product functionality and reliability.

Enter ISO 9001: The Gold Standard of Quality Management

ISO 9001 is a globally recognized standard that outlines the requirements for a quality management system (QMS). Developed by the International Organization for Standardization (ISO), ISO 9001 provides a framework for organizations to establish, implement, maintain, and continually improve their quality processes.

ISO 9001 – a Process-based Approach

At its core, ISO 9001 emphasizes a process-based approach to quality management, focusing on areas such as customer satisfaction, leadership, engagement of people, process improvement, evidence-based decision making, and relationship management. By adhering to ISO 9001 principles, organizations can enhance operational efficiency, mitigate risks, improve product quality, and ultimately, increase customer satisfaction.

- Quality Management System (QMS) ISO 9001 requires organizations to establish, implement, maintain, and continually improve a quality management system. For metal tube bending manufacturers, this means developing documented procedures and processes to ensure consistency, traceability, and compliance with customer requirements and regulatory standards.

- Customer Focus: ISO 9001 places a strong emphasis on understanding and meeting customer requirements. Contract manufacturers must actively engage with clients to identify their needs, preferences, and expectations, delivering products that align closely with customer specifications. Effective communication minimizes the risk of misunderstandings or errors.

- Standardized Processes: ISO 9001 requires contract manufacturers to document and standardize their processes, ensuring consistency and repeatability in production. This reduces variability and minimizes the likelihood of defects or errors, leading to higher quality outputs

- Risk Based Management: ISO 9001 promotes risk-based thinking, requiring manufacturers to identify and assess potential risks that could affect product quality or delivery schedules. By proactively addressing risks, such as supply chain disruptions or process failures, manufacturers can mitigate adverse impacts and ensure smoother operations.

- Continuous Improvement: Continuous improvement is a fundamental principle of ISO 9001. Metal tube bending manufacturers are required to monitor, measure, analyze, and improve their processes systematically. This may involve conducting regular audits, analyzing performance data, implementing corrective actions, and seeking feedback from customers and stakeholders to drive ongoing enhancement.

- Documentation and Records Management: ISO 9001 mandates the establishment and maintenance of documented procedures and records to support the QMS. This ensures transparency, traceability, and accountability throughout the manufacturing process, facilitating effective quality control and regulatory compliance.

Quality control is not merely a checkbox to be ticked off but a philosophy to be embraced wholeheartedly. ISO 9001 certification serves as a powerful tool for achieving excellence. By prioritizing industry standards and certifications, implementing meticulous QC processes, and fostering clear communication throughout the manufacturing journey, contract manufacturers can uphold the highest standards of excellence and forge lasting partnerships built on trust and reliability.

As your trusted partner, Leonhardt Manufacturing is committed to helping you bring your products to life with precision and reliability. Contact us today to discover how our expertise and dedication can support your manufacturing needs.