PRECISION END FORMING

TUBE END FORMING FOR ALL METAL ALLOYS

Home / Capabilities /

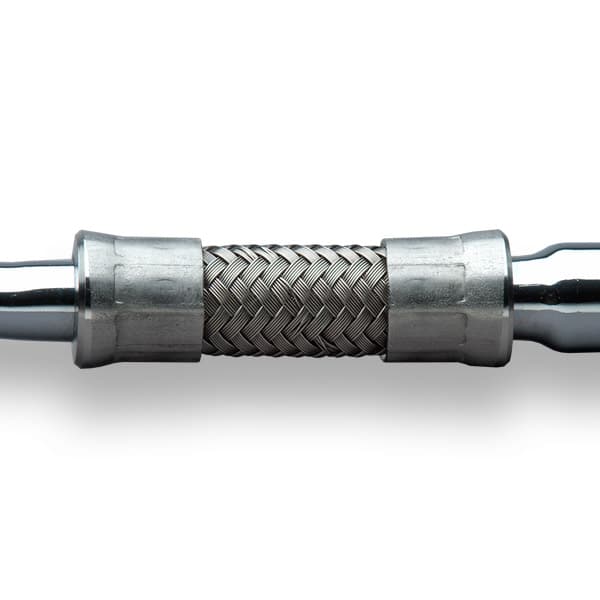

Leonhardt Manufacturing offers tube end forming capabilities to meet most applications and design requirements including tube swaging, flaring, flanging, beading, bulging, chamfering, crimping, tapering, notching, rounding and more. End form processes can be applied to tubing from small hypodermic sizes up to 3″ outside diameter tubing. Tube end forming for all types of metal alloys including aluminum, copper, brass, and stainless steel is available.

Leonhardt can meet standard industry classifications generally associated with tube end forming for specific connection or pressure specifications. In addition, custom end forming requirements can be met for most applications.

Tube End Forming Capabilities

- Expanding

- Reducing

- Swaging

- Flaring

- Coping

- Bending

- Tube End Finishing Capabilities

- Drilling

- Machining

- Milling

- Roll Groove

- Threading

THE LEONHARDT ADVANTAGE

- Work to Customer Specifications Regarding Materials, Tolerances, Performance, Durability, and Cost.

- 95,000 Square Foot Manufacturing Facility

- Compound Tube Bending / Multi-Radius and Variable Radius CNC Tubing Bending

- CNC Robotic MIG Welding and TIG Welding

- ASME Certified Welders

- Metal Stampings and Sub-Assemblies

- Lean Manufacturing Processes Ensure High Efficiency and Quality at the Lowest Possible Costs

- Supply Chain Management Services Streamline your Manufacturing and Lower Costs by Combining Multiple Processes, Suppliers and Asset Management

DELIVERING SOLUTIONS

TO COMPANIES LOOKING FOR:

- Heavy Duty, Industrial, Structural, or Custom Metal Fabrications Manufacturing

- Reduced Expenses Through Lean Manufacturing, JIT Delivery, and Streamlined Supply Chain Management

- Fabricated Components at Production Quantity Levels

- Exacting Product Tolerances

- A Supplier Who Understand The Unique Demands of OEMs

FEATURED JOB STORY

AME Features Tour of Leonhardt Manufacturing’s LEAN Facility

Leonhardt Manufacturing was proud to be a featured stop for the Association for Manufacturing Excellence tour showcasing their excellence in LEAN manufacturing techniques including Value Stream Mapping, cellular manufacturing, Kanban, Poka-Yoke, and visual management.